BENDING –

PLASMA CUTTING

BENDING AND FORMING – PRESS BRAKES

A metal press brake is a machine tool for sheet metal and plate bending. Recent improvements include a “backgauge” – a device that can be used to accurately position a piece of metal so that the brake puts the bend in the correct place. KOMO Metform Engineering provides expert services for bending heavy-gauge steel and bending medium-gauge steel using Australian-made press brake machinery. Pressing capabilities up to 25mm thick by 12 metres x 2000T.

With a large variety of materials from which to choose, KOMO Metform Engineering has the dedicated staff to handle press braking, up-ending and more.

PROJECTS

PLASMA CUTTING DRILLING CENTRE PLATE

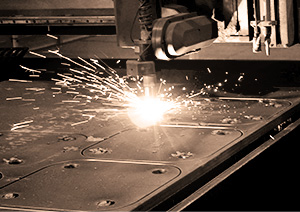

PLASMA Cutting is a process that is used to cut steel and other metals of different thickness. At KOMO Metform Engineering we specialise in medium and heavy-gauge steel cutting. For this process, an insert gas is blown at high speed out of a nozzle to the surface being cut.

KOMO Metform Engineering provides accurate, high-definition plasma cutting for medium-gauge steel as well as plasma cutting for heavy-gauge steel. We have the latest technology in high-definition plasma cutting with software updates annually (USAPRONEST). We also provide a plasma cutting service that involves heavy metal beveling. This steel beveling is done using our bevel head weld prep high-definition plasma cutting machine.

PROJECTS